Lake Michigan Wire specializes in the large diameter end of the wire-form spectrum. We are uniquely equipped to produce the highest quality components manufactured to your exacting specifications.

Our Wire Forming Process

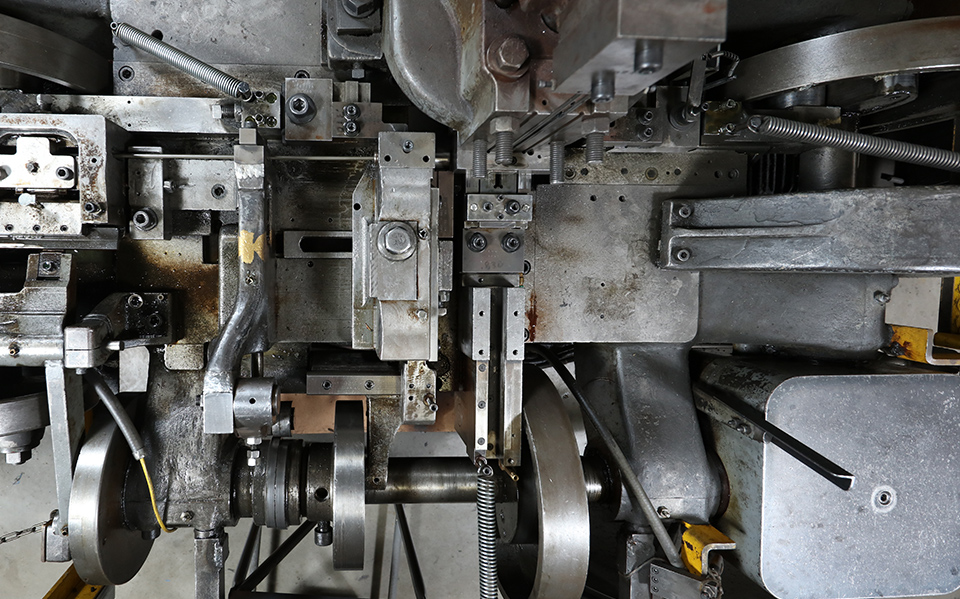

Wire forming is a process used to bend metal and create customized shapes for manufacturing processes. We feed wire from coil through wire grooves into the bed of wire forming machines. From there the wire can be formed into the desired profile using multiple actions that guarantee geometry to precise dimensions and specifications. We can form developed lengths up to 36” with a diameter range of .187” to .551”.

Lake Michigan Wire can also marry our wire forming capabilities with our wire straightening and cutting and secondary operations for applications requiring more than the standard forming process such as:

- Swedge and pierce

- Broaching

- Welding

Many industries require custom wire forming, including aerospace, automotive, construction, and agriculture. The wire-form components we manufacture are used in interior car seat applications, under hood striker forms, in seat belt assemblies, and for commercial applications where quality and price are driving forces in the market.

Our wire forming capabilities are second to none in the large diameter wire spectrum. Our fourslide capabilities allow for tight tolerances that are repeatable over large production runs.

Whether your company’s requirements call for a simple wire form or a highly complex one, count on Lake Michigan Wire to be your wire forming experts. We deliver quality products on time at a competitive price to our customers so they can deliver the same to theirs.

Request a free quote for your project today.